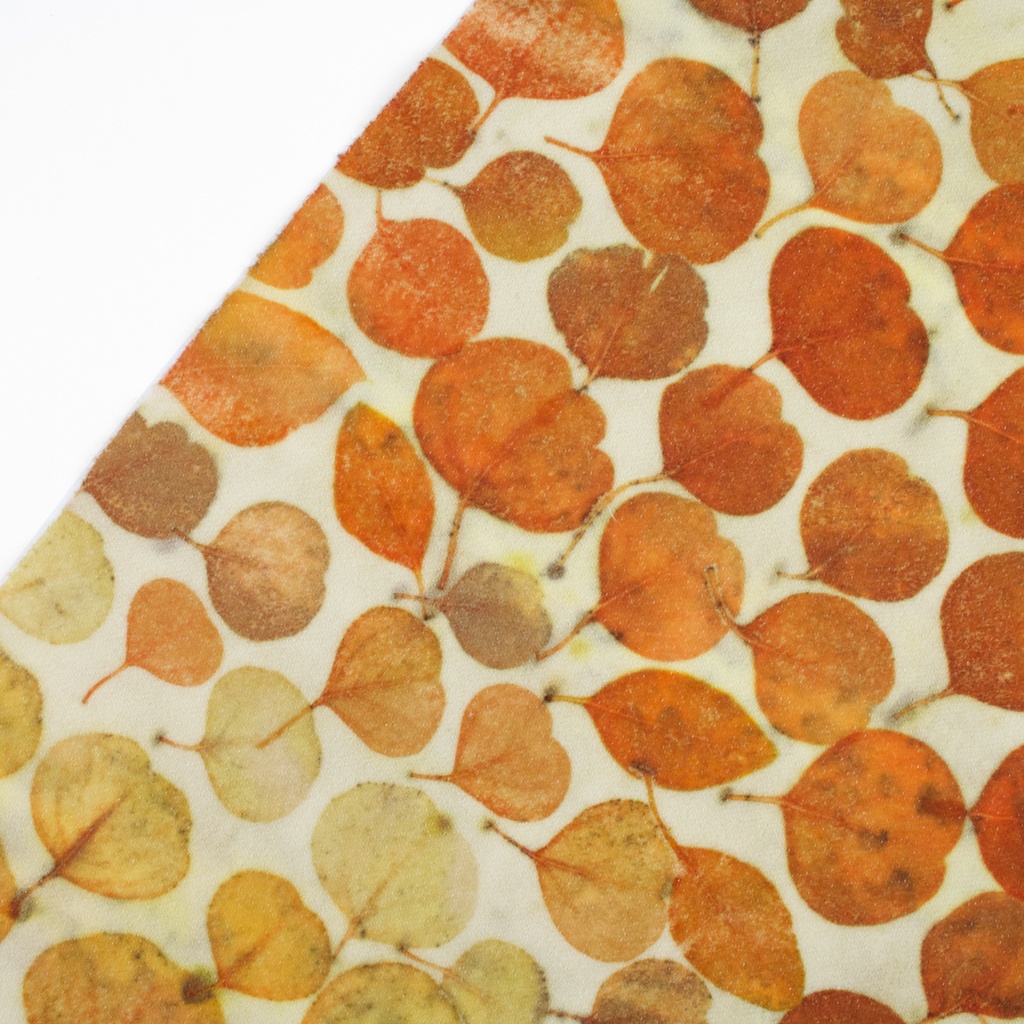

Eco Printing is a form of natural dyeing that creates beautiful, organic fabrics. Different techniques can be used to create either soft forms of color resembling ombré or more graphic prints representing the plants used to create them. Environmentally friendly, this can be done simply by using just the plants and leaves around your backyard!

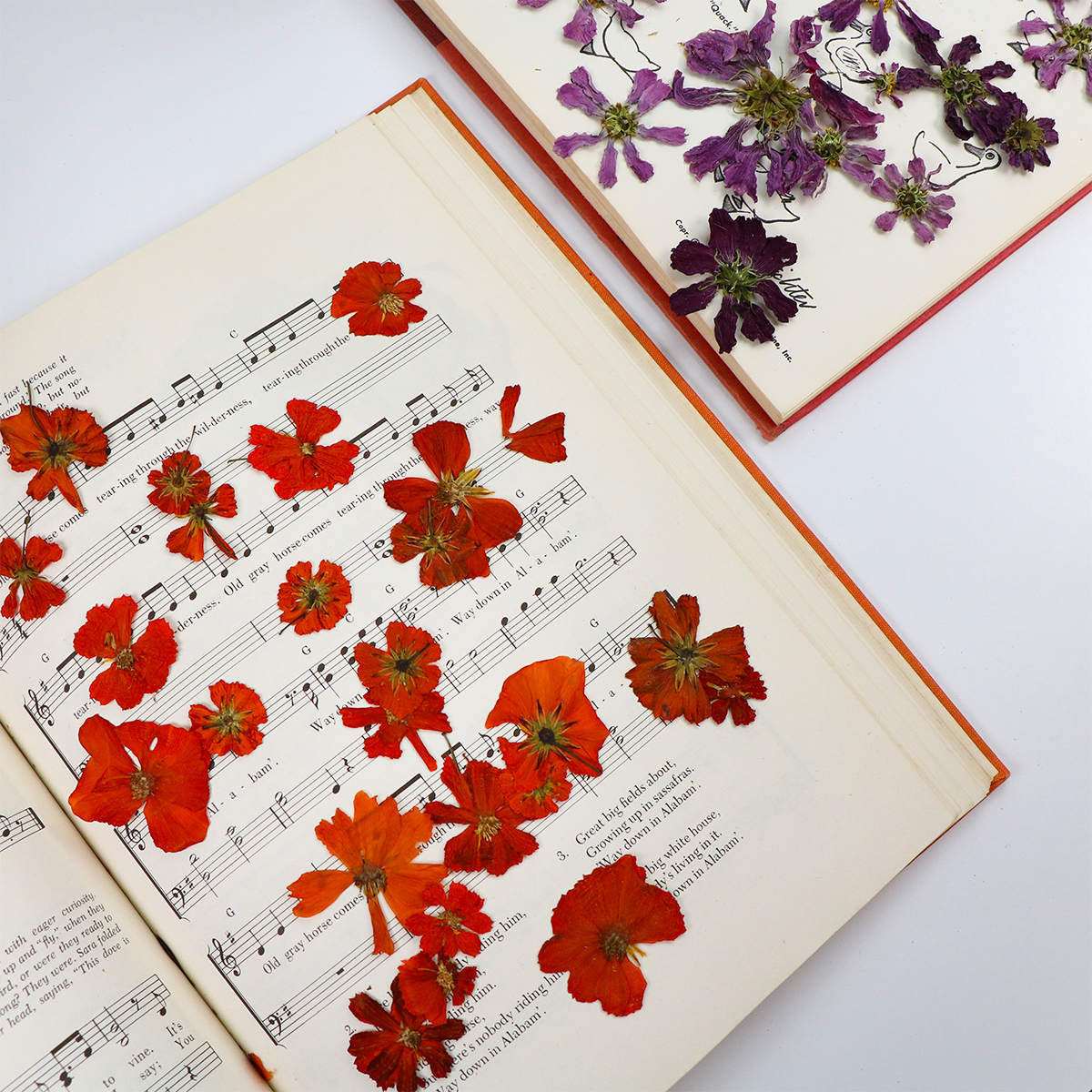

These beautiful pressed flowers and dried eucalyptus leaves will eventually make their way into the eco printing process.

Our Dye Room Technician, Ryan, can be seen here punching shapes out of leaves to use in eco printing. We are always experimenting with new and creative ways to blend nature and art.

Before starting the dyeing process, some projects may need a mordant bath first. Depending on the fabric you choose, generally cotton, linen, or silk, and the plant material used in the dye bath, usually leaves or flowers, the mordant bath may drastically change or enhance the final result.

Once they’ve been given their first bath, the damp fabric is laid out. Plant material is then laid flat on top of one side of the fabric. There are so many ways to experiment with this step! Adding other items, such as fruits and vegetables, stones, and small rusted metal items, along with the more common leaves and flowers, can create many different effects.

After the plants are arranged on the fabric, another piece of fabric is laid on top of them.

The fabric sandwich is then tightly rolled around a cylinder, such as a PVC pipe or a wooden dowel. The roll is secured with a layer of plastic wrap, or it can be tied with cotton thread or twine. Colorfast threads are very important for this step, as they can bleed onto the base fabric.

Ryan is ready for the next step! Using either a pot of boiling water or a double level steamer, it’s time to steam the fabric! This is the step in the process that pulls pigment from the plants and into the textile being dyed. Just like natural dyeing, eco printing isn’t an exact science, and depending on the materials used, it could take anywhere from 1-2 hours for this step to be complete. Part of the fun of eco printing is experimentation! Playing with different materials, plants, and times all provides new results to discover!

Once it’s finished steaming, the fabric needs to cool. Depending on personal preference and the results of experiments, the fabric could be left to rest for anywhere from an hour to a full day. Once it’s finished resting and is fully dry, it can be gently washed. With eco-printing, the end result is a soft and organic display of the colors nature provides.

The Hand Quilted Zipper Pouch, Swag Bag, and Modern Japanese Rice Pouch are absolutely stunning examples of the beautiful earthy softness that eco printed fabric brings to any project.

Hand Quilted Zipper Pouch: Kit・Pattern

Collaborate with Mother Nature and let the beauty of eco printed fabric guide you in your next creative endeavor!

Shop our Specialty Wool Page for the newest eco prints and more!